Hot bent glass , curve glass ,Hot Bent Curved Glass ,Clear Bending Tempered glass ,thermal bending glass ,furniture glass

Hot Bent Glass

is a curved glass made by heating and softening flat glass to form in a mold and then annealing. Hot bent glass is generally processed in an electric furnace. Continuous hot bending furnaces generally have 5-6 chambers, 11-13 stations, and a finished product can be produced in about tens of minutes. The batch type hot bending furnace generally has only one chamber, and the temperature forming and annealing are completed in o ne room. The processing cycle takes several hours to one

PRODUCT FEATURES

Aesthetics

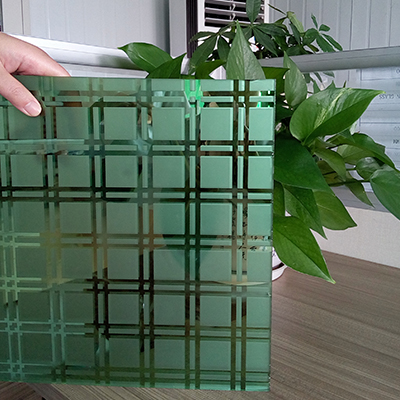

The curved tempered glass breaks through single shape of ordinary flat glass, the style is unique and beautiful, the lines are softer and smoother, so it is more flexible in application. It is often used in aquariums, counters, curtain walls, turnstiles, etc. Enhance beauty and quality through a unique look. In order to meet requirements of customers for home decoration, hot bent glass is also commonly used for walls, ceilings, doors and windows. Due to the soft curved glass lines, the home environment can be more natural and harmonious.

Specificity

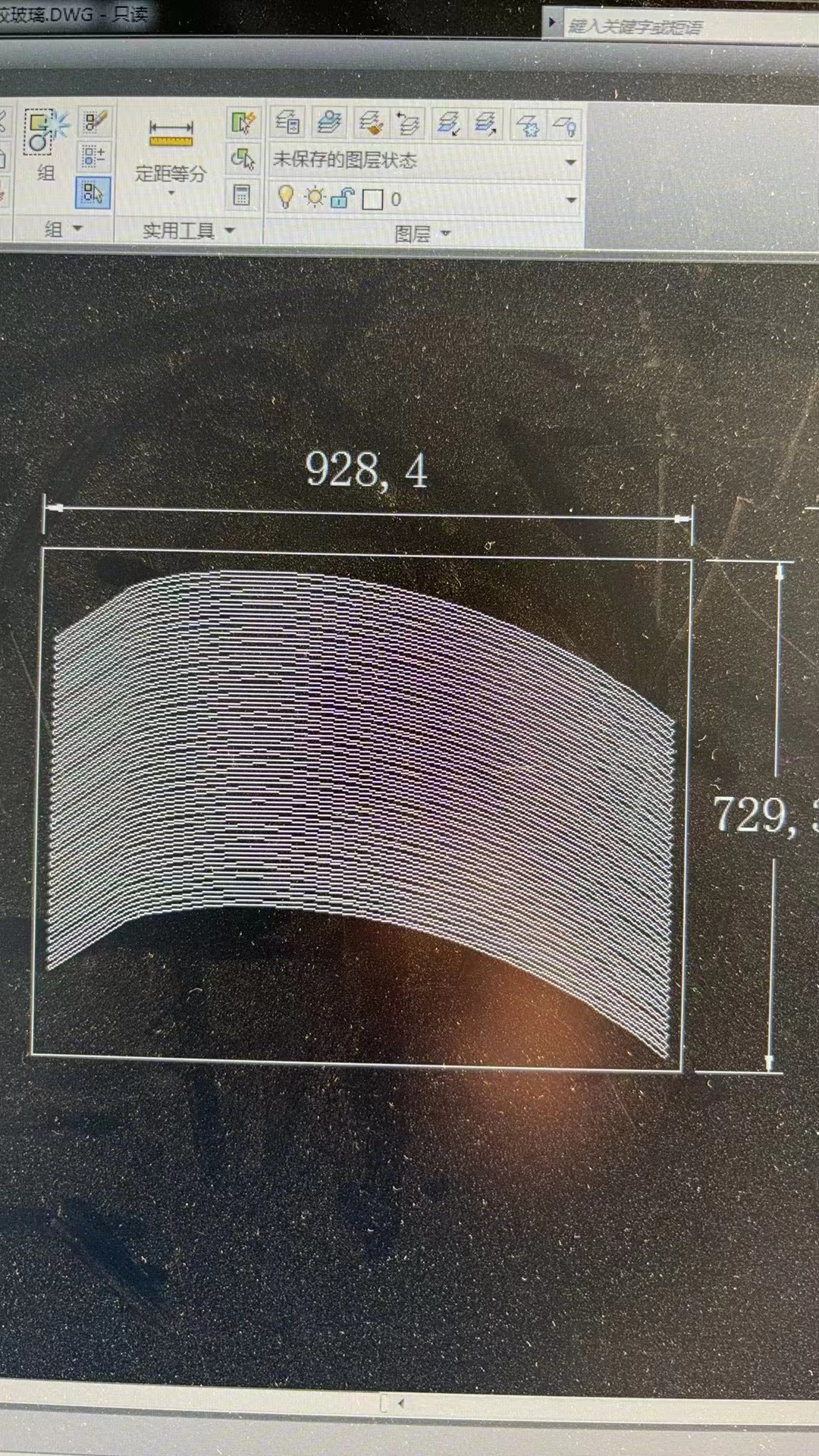

According to different shape requirements, it can be customized for various irregular curved surfaces, and even can be produced into hollow or laminated various types of composite curved glass products. Due to this feature, hot bent glass is unusually popular in the construction and civilian markets. Building hot bending glass is mainly used for interior and exterior decoration of buildings, lighting roof, sightseeing elevators, arched corridors, etc.

Custom

Hot bending glass can be customized according to the actual requirements of customers, the hot bent glass price will be different or will be high to some degree.

TYPES:Hot bent glass is classified by shape

(1) Single Bent Glass

For a single curved architectural glass, glass bending is relatively easy. However, many China hot bend glass manufacturers often have a curve edge of approximately 150 mm from the straight side of the product, which cannot be well matched with the mold, and some of them exceed the standard requirements, resulting in difficulty in installation. To solve this problem, it is first required that the electric heating arrangement of the hot bending furnace should be reasonable, and local heating can be realized, and the direction in which the product is placed should be consistent with the direction of the heating wire.

(2) Bending Glass

Commonly used in bending hot-bending glass are aquarium glass and counter glass. The biggest technical difficulty of bending glass is that the straight side is curved, and the corner is prone to mold defects. Therefore, curved glass is also very common, such as spherical glass, curved arched profiles, glass wash basins, etc. This glass requires a high level of skill in hot bending operations, making precise molds, and some require professional heat. The curved furnace can be completed.

(3) Composite Bent Glass

Compound curved glass is also common, such as spherical glass, curved arched corridors, glass wash basins, etc. This kind of glass requires a high level of skill in the hot bending operation mountain, making accurate molds, and colleagues need professional hot bending. The furnace can be completed

Therefore, the price of hot bending glass is different according to different types and technical requirements, and the hot bent glass price change is also very obvious.

Booming Glass comply with China GB15763.2; Europe EN12150-1;

USA ASTM C1048; and Australia AS/NZS2208.

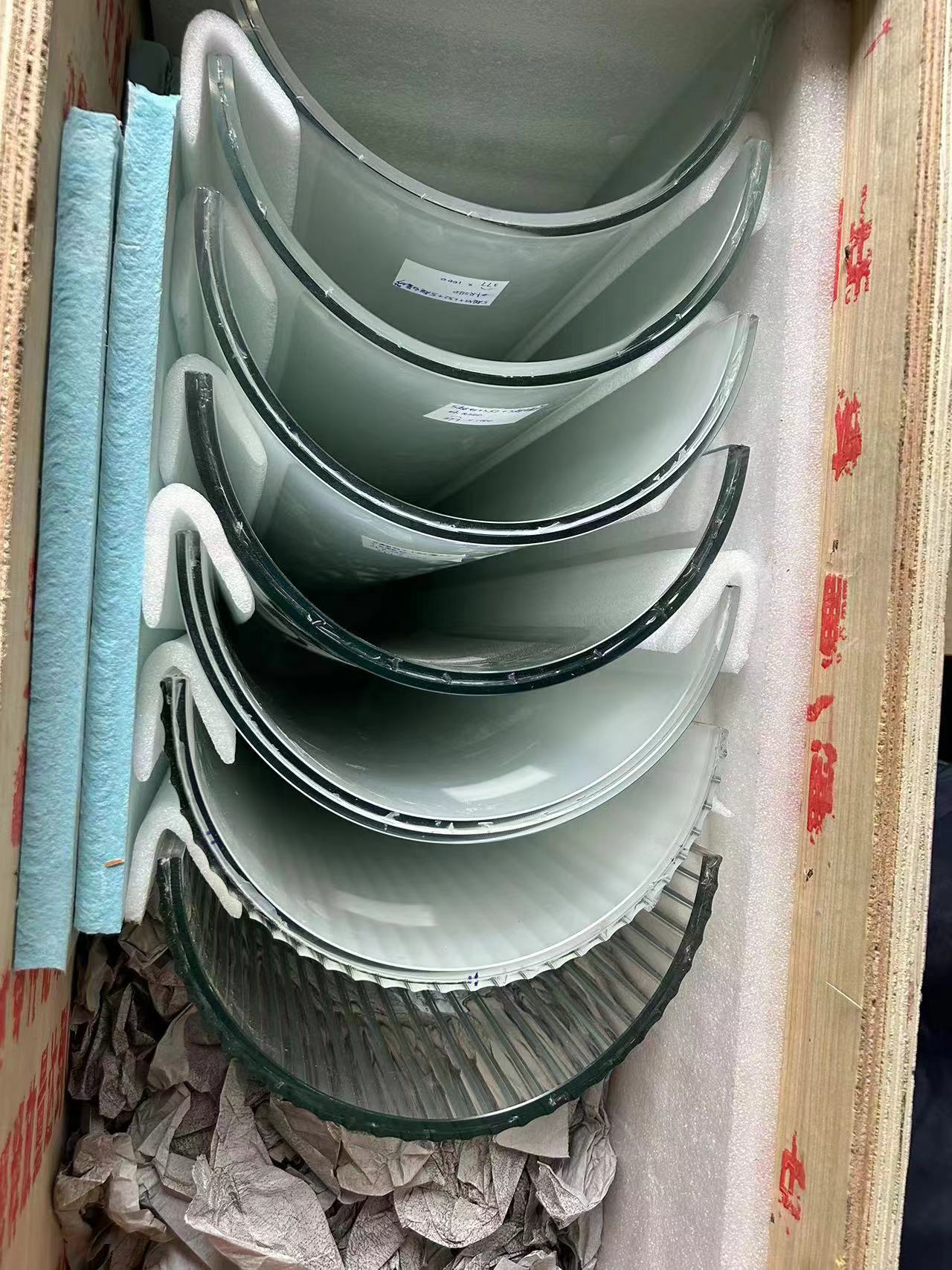

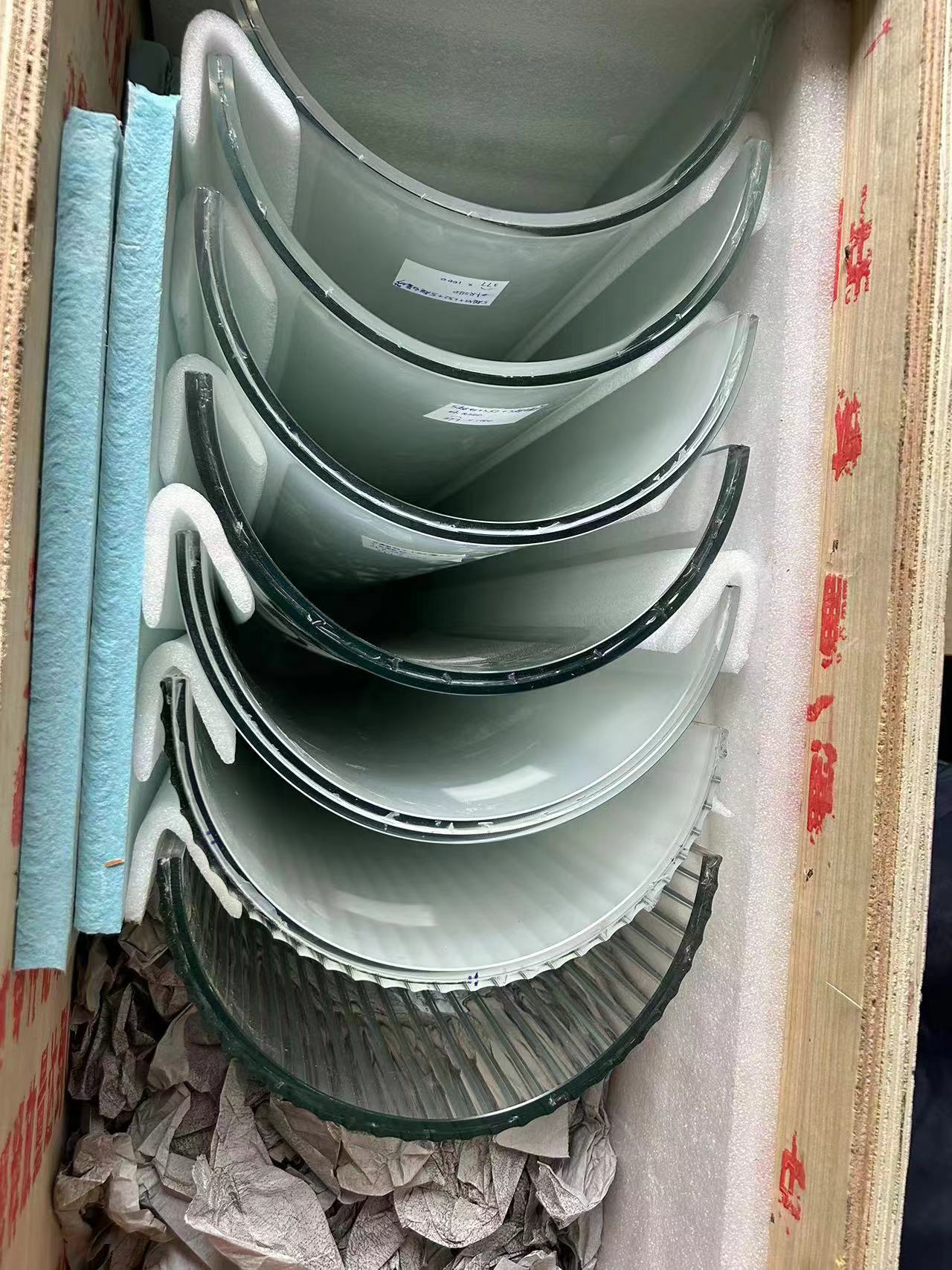

PACKING AND LOADING