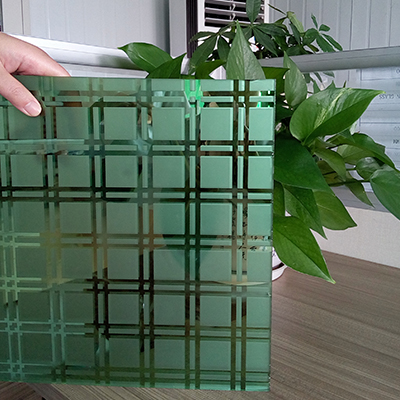

Curve tempered glass ,Bending tempered glass ,Tempered glass

Tempered Glass Products:

tempered glass belongs to safety glass. It is obtained by cutting ordinary annealed glass into the required size first, then heating to about 700 degrees close to the softening point, and then performing rapid and uniform cooling (usually 5-6MM glass is heated at 700 degrees for about 240 seconds and cooled for about 150 seconds. 8-10MM glass is heated at a high temperature of 700 degrees for about 500 seconds and cooled for about 300 seconds. In short, depending on the thickness of the glass, the time for choosing heating and cooling is also different).

tempered glass is tempered, the surface of the glass forms a uniform compressive stress, and the internal tensile stress is formed, so that the bending and impact strength of the glass can be improved. Its strength is about four times that of ordinary annealed glass. When the glass bears external forces, First offset the surface compressive stress, thereby improving the bearing capacity, improving the glass's own stress resistance, cold and heat resistance, impact, etc.

tempered glass that has been tempered can no longer be cut, ground or damaged, otherwise it will be "broken to pieces" due to the destruction of uniform compressive stress balance ".

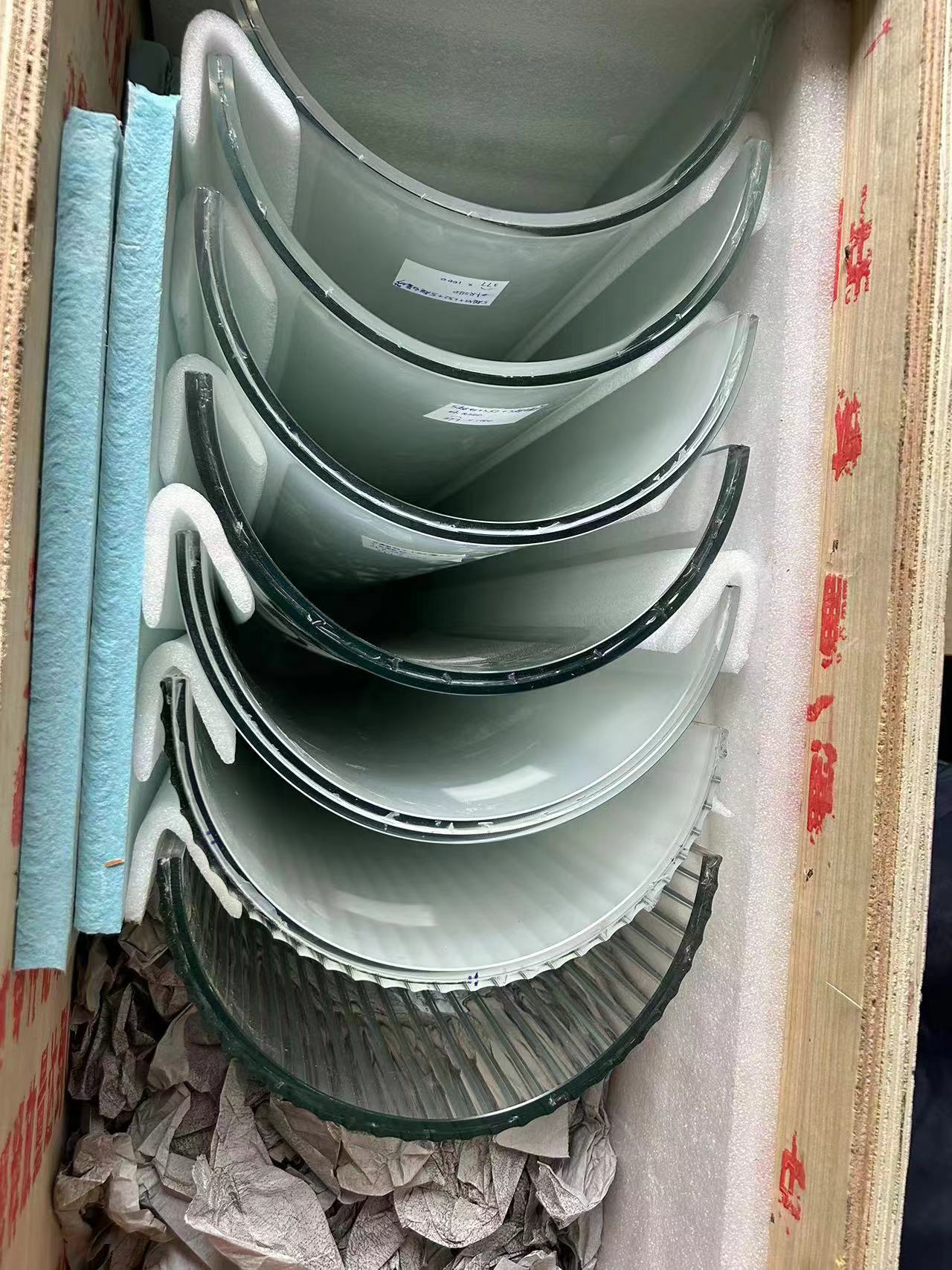

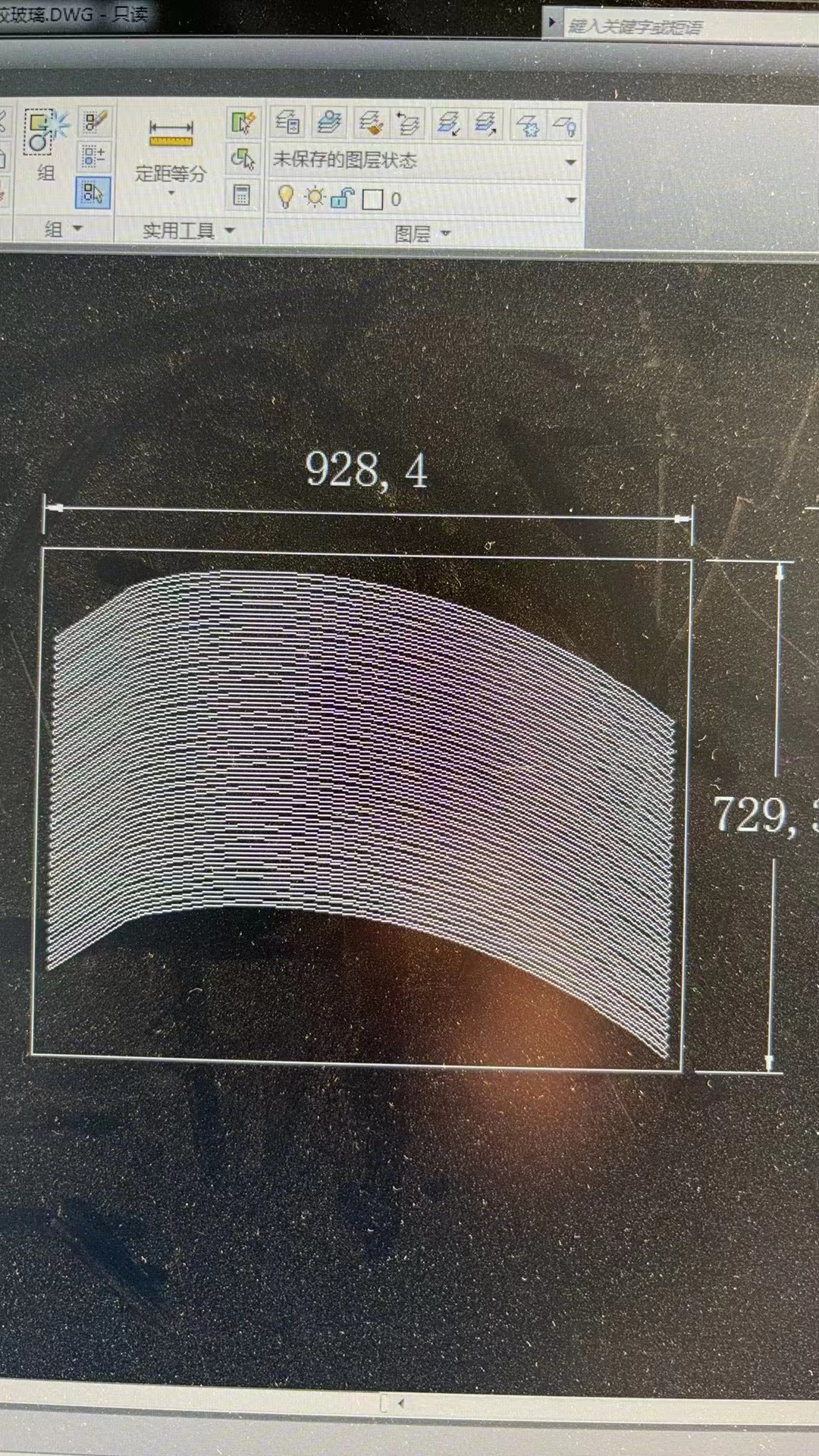

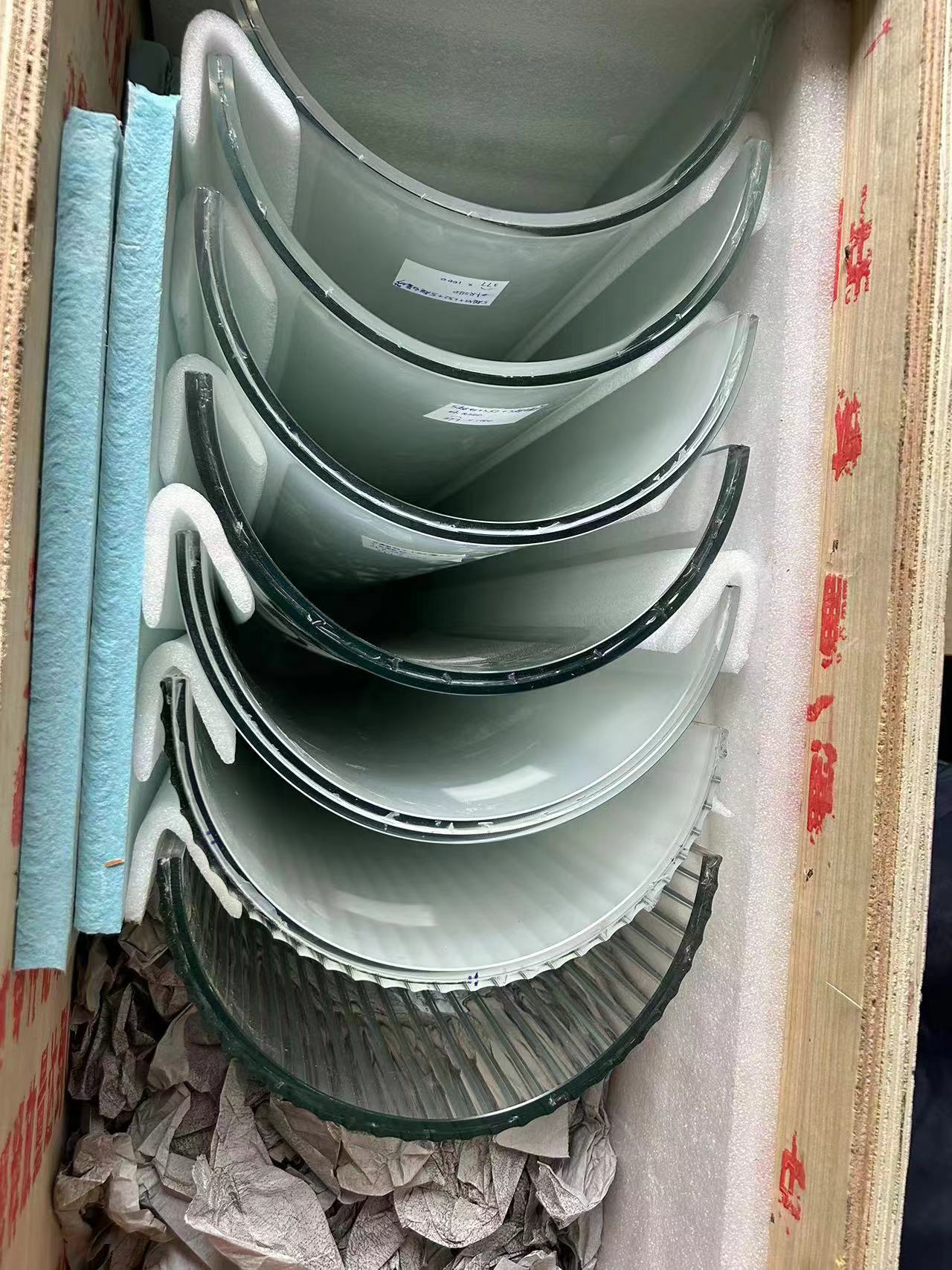

Curve tempered glass production process:

After cutting, edging, cleaning, drying, tempering furnace and heating, the glass will be red after heating, and the steel bending machine will lift the glass into the lower bend, fix it, and then cool it by the fan

transportation: